Energy Storage Safety① ---Multi-dimensional solutions

With the steady promotion of the national "dual-carbon" strategy, the energy structure is changing at a faster rate than expected, the proportion of new energy in operation is increasing, and the rapid development of new energy wind and light on the power generation side is synchronized with the upgrading of grid-side and user-side energy supporting facilities has also ushered in unprecedented opportunities.

Electrochemical energy storage, with its low investment, long life, high return, easy maintenance, recyclable and many other features in the source, network, load, charging and so on the whole energy chain is playing an increasingly extensive role, highlighting the high application and investment value. However, the development of energy storage, can not be separated from an important premise, that is, safety. Energy storage safety is the bottom line of every energy storage enterprise should be, is the moral foundation of every energy storage people, is the necessary course for every energy storage designer, is the fundamental premise of the development of energy storage industry.

The design of energy storage safety involves multi-disciplinary professional knowledge and skills, and should be demonstrated through a large amount of experimental data and operation cases.

Based on decades of technical experience, Huasu New Energy Group has established a complete safety management system to ensure the safe and smooth operation of the energy storage system by considering the overall safety design of energy storage products in multiple dimensions, following the general idea of combining prevention and response, active and passive, and combining active and passive.

The active safety (prevention of safety risks) should include but not limited to the safety of the electric core, the safety of the energy storage structure, electrical safety, soft control design (dynamic risk identification and response), and the passive safety (emergency measures after the occurrence of risks) design mainly includes but is not limited to: temperature and its consistency of the control, fire prevention warning and response, passive electrical protection and other measures.

Electric core safety design

In terms of battery cell material selection, LFP battery material is chosen, with low probability of thermal runaway and slow temperature rise.

In terms of battery cell manufacturing process, the surface of diaphragm is covered with special ceramic coating, which improves the high temperature resistance of the material. High-precision control and anomaly detection technology to ensure product consistency and long-term reliability.

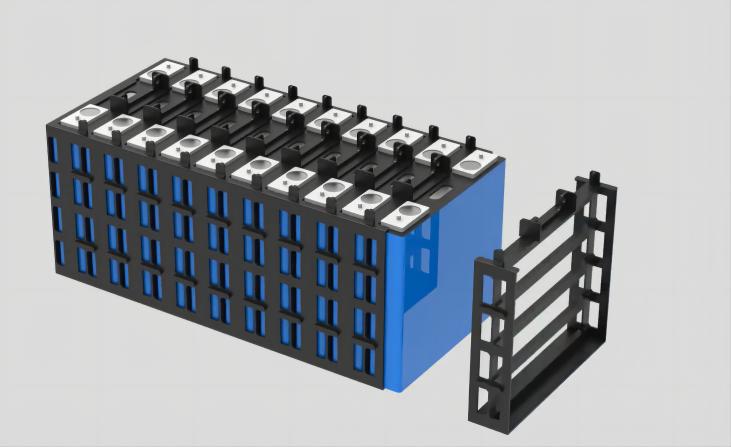

Battery cell structure: The battery shell adopts square aluminum shell design to improve safety performance. The winding-type stacking process reduces the corners of the cathode and anode plates, which greatly reduces the possibility of short-circuit within the battery cell. The top of the battery cover is equipped with a Vent explosion-proof valve to relieve pressure, which can release the pressure inside the battery cell in time, avoiding the safety failure of the battery.

Structural Safety Design

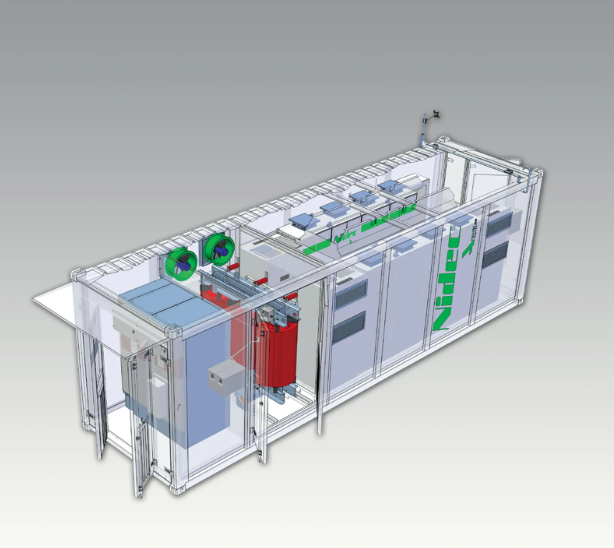

The design of the battery cabinet covers structural, thermal management, anti-seismic and other features, and the design reasonableness under the conditions of transportation, earthquakes, and heat generation has been fully verified through simulation technology.

The frame type cabinet can reduce the resistance of air intake of the electric box and increase air circulation. The surface of the battery cabinet is electrostatically sprayed, and all metal structural parts are treated with special anti-corrosion treatment. The internal high-voltage connection adopts high-voltage quick-plug connectors, and the design of the electrical clearance and creepage distance needs to comply with the IEC62477 standard.

In addition, there is a gap between each battery cell for ventilation and heat dissipation or a special cooling liquid plate is added. Even if the single cell has runaway heat, the heat can be dispersed at any time without causing heat spreading to ensure the daily operation of the system.

Management System Safety Design

The BMS three-level management structure can intelligently monitor the operation of the energy storage system in an all-round way. During the charging process, the battery terminal voltage of all batteries in the system is ensured to be consistent by adjusting the charging current of a single battery. It not only monitors various battery parameters such as voltage, current, temperature, insulation, SOC, etc., but also reads real-time data through the serial port, realizing the functions of BMS data monitoring, data dumping and battery performance analysis.

In addition to data monitoring, BMS also has a thermal management function. If the battery is over-temperature or the temperature difference is large, it will automatically start the electric cooling device, so that the temperature of each area tends to balance. For exceeding the temperature range that the battery can withstand, the management system will limit the operation of the battery.

Electrical Safety Design

The battery system utilizes three levels of relay protection. The first level relay, when the overcurrent phenomenon is recognized, the system first allows the relay to trip, to ensure that no harm is done to the current; the second level circuit breaker, when the relay can not be pulled off due to DC overcurrent arcing, the circuit breaker can achieve further overcurrent protection and short-circuit protection; the third level fuse, when the circuit breaker also fails and can not be disconnected from the circuit, then the fuse to achieve the third level of protection, to ensure battery system safety.

Fire protection system design

The fire protection design of the containerized energy storage system adopts the pipe network heptafluoropropane (or perfluorohexanone) fire extinguishing system, and uses the intelligent device for prevention and control of thermal runaway fire. It realizes early fire sensing, intelligent judgment and suppression of early fire in the battery part, and has the functions of early warning of thermal runaway of the battery, automatic fire extinguishing and manually activated fire extinguishing.

Four levels of fire warning, corresponding to the latent period of the fire process, the warning period, the alarm and the open fire period. The first level of early warning for internal use of the system (no external report); the second level of early warning for the gas sensor to detect the "concentration" of abnormal, smoke sensor detects the "visible smoke" when the early warning; the third level of early warning for multi-sensor (gas, smoke and temperature) composite judgment of the abnormal Early warning; Level 4 warning in the second and third level on the basis of temperature sensors to detect the "temperature characteristics" abnormal and have a clear upward trend of early warning.

Product safety is designed, as a domestic specialized energy storage solution provider, thanks to decades of technology accumulation, Huazhu New Energy Group has a deep understanding of battery safety. It always runs through the design concept of safety, intelligence, convenience and high efficiency as the core of energy storage, and contributes wisdom and strength to the healthy and rapid development of the energy storage industry.

Huazhu New Energy Group, a 37-year-old energy solution provider, has long been committed to the design, development and application promotion of energy storage products, adhering to the corporate philosophy of "providing the world with safer and cleaner energy", and providing customers with one-stop solutions for energy security.